Against the backdrop of the rapid development of functional textiles today, Technology Velvet Fabric has gradually become a dark horse in the home textile, clothing and home furnishings industries. It not only retains the soft, delicate, lustrous and warm touch of traditional velvet, but also integrates the functional upgrades brought by modern technology, such as antibacterial, breathable, antifouling, and wear-resistant, making it stand out from many fabrics.

What is Technology Velvet? The core difference from traditional velvet

Traditional velvet is famous for its high density, short pile, and soft touch, but it has some disadvantages, such as easy to absorb dust, not washable, and single function. Technology velvet is an innovative product that integrates traditional velvet with functional fiber technology. Its main features include:

Use high-tech synthetic fibers (such as polyester, nylon, regenerated cellulose, etc.);

Incorporate surface treatment processes such as nano-coating, antifouling, waterproofing, and antistatic;

Improve the compactness and stability of the velvet surface through three-dimensional weaving technology;

Adapt to digital printing and functional coating, more modern and practical.

This type of fabric not only maintains a "luxury" visually, but also surpasses traditional velvet in performance, achieving a leap from "decorative" to "functional".

High-end and practical coexistence: Analysis of the advantages of technological velvet

1. More delicate texture and stronger skin-friendliness

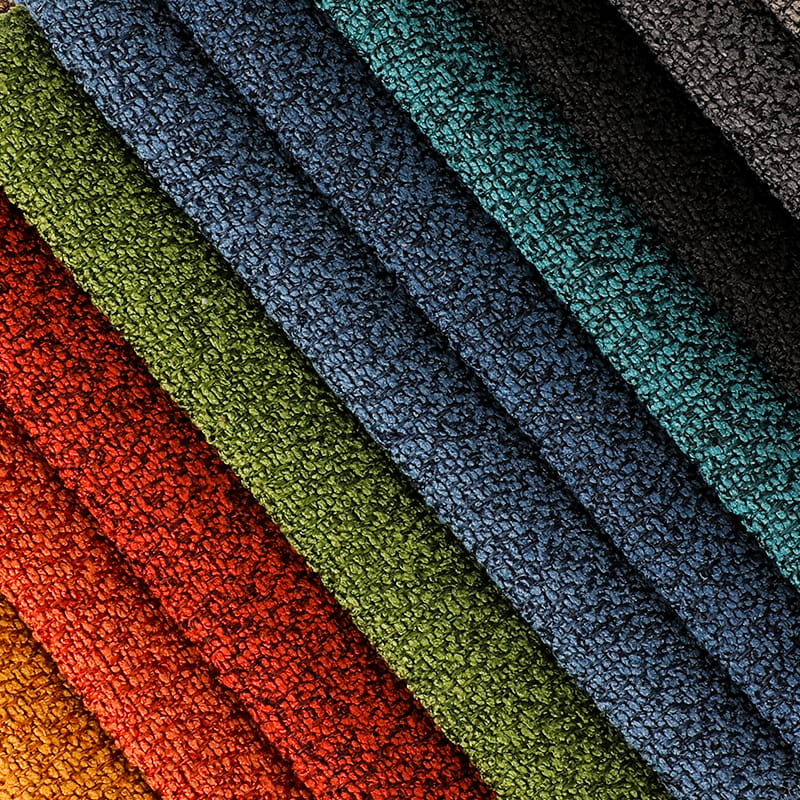

Technological velvet fabrics are more refined in fiber processing, with shorter and denser fluff, and a touch that is almost "milky smooth", more skin-friendly than ordinary velvet, and suitable for direct close contact.

2. Powerful functional blessing

Antibacterial and mite removal: Silver ion or nano zinc oxide treatment is applied to effectively inhibit bacterial growth, especially suitable for use in infants and pet families;

Anti-fouling and waterproof: The surface nano coating forms a "lotus leaf effect", which makes it difficult for liquids and stains to penetrate, making cleaning more convenient;

Anti-static treatment: Effectively reduce the trouble of static electricity in winter and increase the comfort of wearing or using;

High wear resistance: Suitable for high-frequency use scenarios such as sofas, pillows, curtains, etc., not easy to pilling or fading.

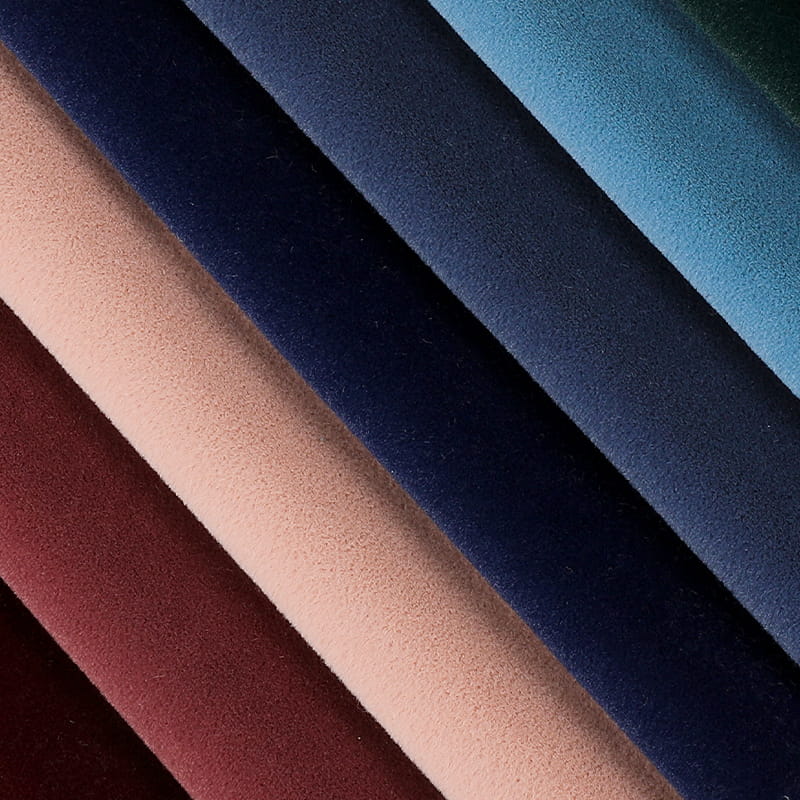

3. Rich colors, suitable for a variety of design styles

Due to the use of functional polyester fiber or microfiber, technological velvet has stronger adhesion and color fastness in dyeing, can present more delicate gradient colors and texture effects, and is widely used in modern minimalist, French retro, and light luxury styles.

Typical application scenarios of technological velvet

Home furnishing field: the first choice for creating quality life

Sofa fabric: technological velvet is an ideal choice for high-end sofas because of its wear resistance, easy cleaning, and rich colors;

Curtains and soft furnishings: It has good drape and strong light-shielding properties, which can enhance the overall texture of the space;

Bedding and pillows: skin-friendly and soft, antibacterial treatment improves safety of use, and is widely popular.

Clothing field: materials with both fashion and function

Technological velvet is gradually entering the field of mid-to-high-end fashion clothing, suitable for:

Autumn and winter coats and jackets;

Children's and pregnant women's home clothes;

Haute couture dress fabrics, etc.

Through digital printing and laser embroidery technology, the fabric has a strong expressiveness, combining beauty and performance.

Automotive interior and high-end packaging materials

Technology velvet is widely used in car seats, car roofs and other parts, and even high-end electronic product packaging due to its high temperature resistance, environmental protection and high-quality texture.

Future trends: How will technology velvet fabrics evolve?

With the development of the concepts of "sustainable fashion" and "smart textiles", technology velvet is evolving in the following directions:

Green and environmentally friendly trends: Recycled velvet made from recycled PET bottles is used to promote low-carbon textiles;

Smart temperature control function: Add phase change materials or graphene coatings to regulate body surface temperature;

Multi-functional integration: Integrate composite properties such as waterproof, flame retardant, antibacterial, and deodorizing;

3D printing and digital weaving: Improve design freedom and create customized textures.

Technology velvet fabrics are not only an upgrade of traditional velvet, but also represent the future direction of fabrics that coexist with functionality and beauty. In the era of consumption upgrades and personalized customization, it has won market favor with its "soft power" and will also release greater potential in many fields such as home furnishings, clothing, and automotive use.

English

English Español

Español